The optimisation of droplet size and distribution is controlled by the user when adjusting the nebulisation gas flow. If the droplet size is too small, the resulting particle size will limit the sensitivity at the detection stage. If the droplet size is too large, it will either drain to waste, which limits the amount of sample that is transported to the optical region or will result in high noise from insufficient evaporation. The droplet size must be optimised to ensure it is as large as possible yet still able to evaporate the solvent along the drift tube. The aim of nebulisation is to produce a narrow distribution of droplets. The detector’s sensitivity and reproducibility are largely determined by the quality of nebulisation. The initial nebulisation step within ELSD is fundamental to the performance of the instrument. Gas flow and temperature can be adjusted to optimise the response of the ELSD. The amount of light scattered is then measured. The liquid droplets pass into a heated zone where the solvent is removed to leave the dried analyte particle which is subsequently irradiated with light. Liquid flow from a column is nebulised using nitrogen or air to give a plume of fine droplets containing the analyte in solution.

This article illustrates how the technique has evolved to overcome these issues.ĮLSD is based on three well-defined stages, nebulisation, evaporation and detection (Figure 1).

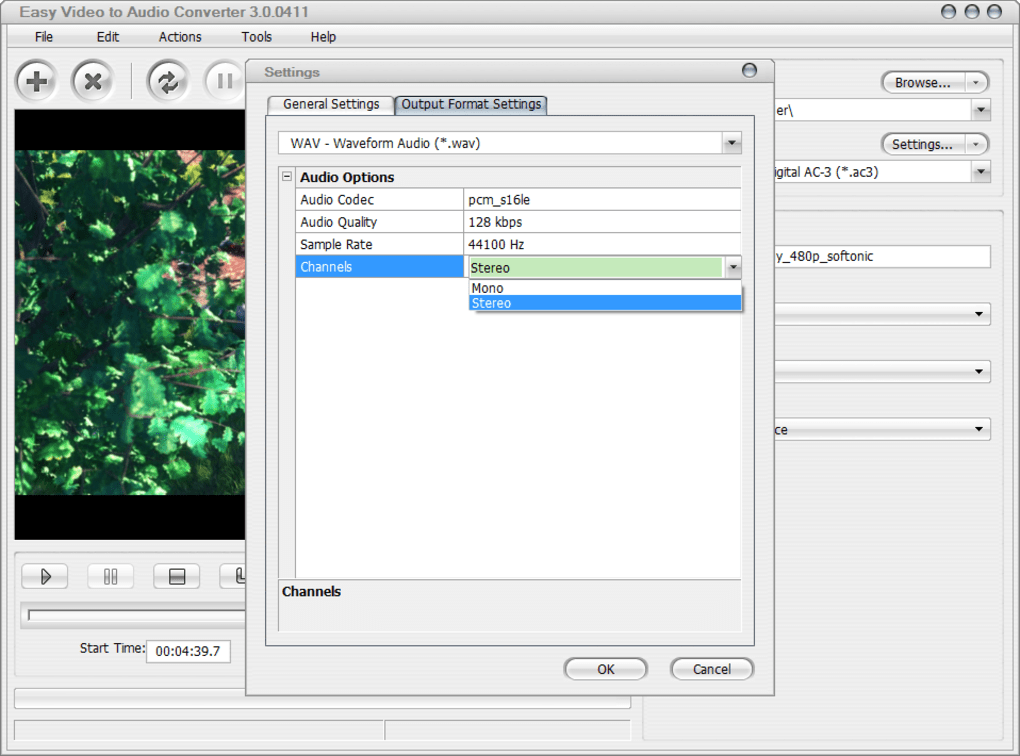

#Easy video converter for premiere full#

Also lack of reproducibility, change in compound response over a gradient and SFC compatibility have been limitations that have prevented the technique from realising its full potential. So although the sensitivity exceeds RID by at least an order of magnitude the quantification of low-molecular-weight compounds has always proved to be a challenge. The past limitations of this detector were its limited sensitivity and dynamic range when compared to UV detection and did not perform well with low molecular weight compounds, which are destroyed by the elevated temperatures employed to remove the solvent from the eluent stream. However over the year’s evaporative light-scattering detection (ELSD) has become a popular detector choice for HPLC/UHPLC. The quest for a ‘universal detector’ started as long ago as 1966, when Union Carbide developed the technique of Evaporative light scattering, the technique wasn’t commercialised until the 1970’s and there was a very slow adoption by potential customers.

The limitations with RID have always been a relative lack of sensitivity, long warm up and equilibration times coupled with lack of solvent gradient compatibility. Refractive index detection (RID) has often been used for carbohydrates, polymers and other compounds mainly based on carbon and hydrogen. However, for compounds that have little or no UV chromaphore, an alternative detection technique is required. UV and diode array have always been the detectors of choice for HPLC/UHPLC because of high sensitivity and linearity of response.

0 kommentar(er)

0 kommentar(er)